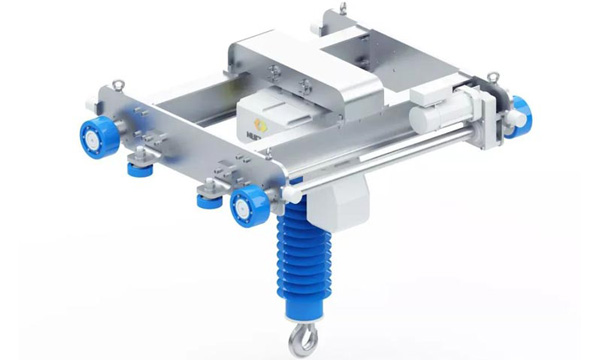

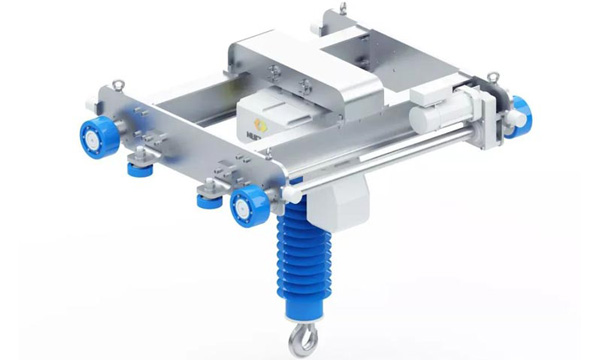

Cleanroom Wire Rope Electric Hoist

1.According IOS, GB, FEM, DIN, and BS standards.

2.Equipped with a third-generation anti-sway control system;

3.Can easily and accurately reach the designated position;

4.Does not affect the cleanliness of the environment lifting equipment.control dust amount.

5.Anti-static design;Adjustable speed, smooth operation...

Introduction

It refers to a specially designed room that removes pollutants such as particles, harmful air and bacteria from the air within a certain space, and controls indoor temperature, cleanliness, indoor pressure, airflow velocity and distribution, noise, vibration, lighting and static electricity within a certain range of requirements. In other words, no matter how the external air conditions change, the indoor environment can maintain the required cleanliness, temperature, humidity and pressure. Clean type hoist crane: used in clean room, does not affect the cleanliness of the environment lifting equipment. Key point is to control dust amount.

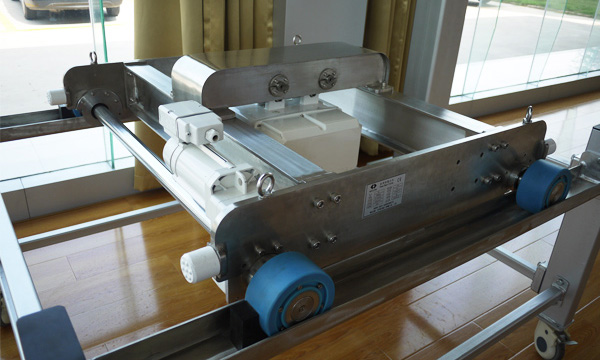

Cleanroom Wire Rope Electric Hoist

Specification

| Cleanliness (N) | Greater than or equal to the maximum concentration limit for particle sizes in the table | USA Standards | |||||

| 0.1um | 0.2um | 0.3um | 0.5um | 1um | 5um | ||

| 1 | 10 | 2 | |||||

| 2 | 100 | 24 | 10 | 4 | |||

| 3 | 1000 | 237 | 102 | 35 | 8 | 1 | |

| 4 | 10000 | 2370 | 1020 | 352 | 83 | 10 | |

| 5 | 100000 | 23700 | 10200 | 3520 | 832 | 29 | 100 |

| 6 | 1000000 | 237000 | 102000 | 35200 | 8320 | 293 | 1000 |

| 7 | 352000 | 83200 | 2930 | 10000 | |||

| 8 | 3520000 | 832000 | 29300 | 100000 | |||

| 9 | 35200000 | 8320000 | 293000 | ||||

Feature

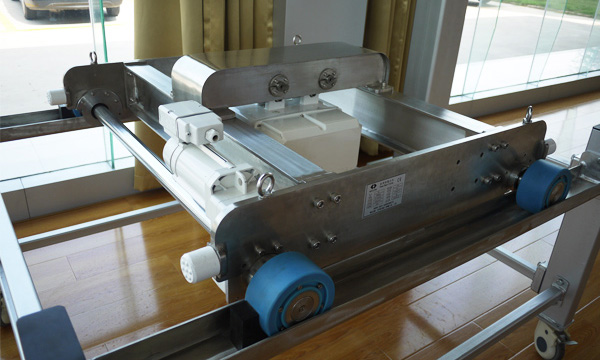

Does not affect the cleanliness of the clean room environment;

No dust adsorption, no friction dust;

Anti-static design;

Adjustable speed, smooth operation, beautiful appearance.

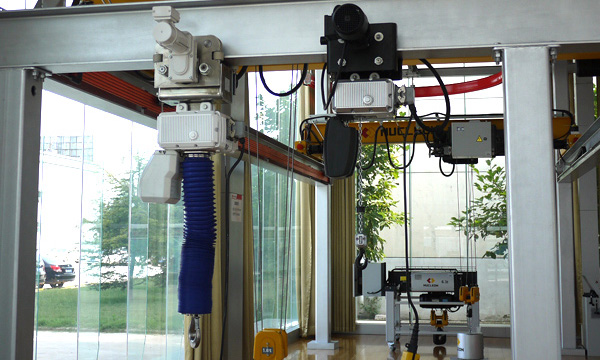

Case:

FAQ:

01Cleanroom classification is based on cleanliness level?

which represents the level of measured contamination from 1 particle at .5µm per cubic foot of air to 100,000 particles at .5µm per cubic foot of air.

Class 1 (ISO 3)

Class10 (ISO 4)

Class 100 (ISO5)

Class 1000 (ISO 6)

Class 10,000 (ISO 7)

Class 100,000 (ISO 8)

02What scenarios are generally used for clean room cranes?

It is specially used in industrial clean rooms and biological clean rooms with strict cleanliness requirements. A clean room is also a special kind of clean room. It usually requires a high degree of cleanliness and does not allow a lot of dust. The interior is generally dominated by white.

The cleaning lifting system integrates technology, construction, decoration, equipment automation and other technologies, and mainly meets the strict requirements of production environment and quality in the fields of electronics, pharmaceuticals, bioengineering, medical care, and laboratories. Compared with cranes in other industries, the cleaning lifting system has the main characteristics of cleanliness, wear resistance, low failure rate, wide speed regulation range, and accurate positioning. Therefore, a clean lifting system is a necessary condition to ensure mass production in industries with high environmental requirements such as liquid crystal panels, photovoltaics, microelectronics, semiconductors, and medicine.