Slab clamp crane

Lifting capacity(t): 35

Span(m): 27.5-35.5

Lifting height(m): 12

Introduction

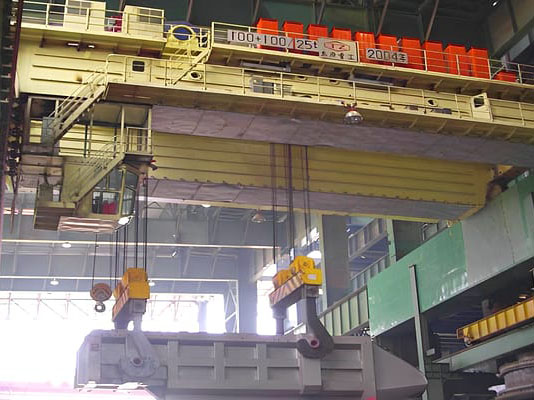

Slab Handling Crane It is a highly maneuverable electric bridge crane, which is mainly used in steel mills. It usually transports large pieces of hot soft metal, either slabs or billets, from the smelter to its next destination. Melting plants are usually separated from other production sites at some distance because the process is very dangerous.

Slab handling cranes need to transport the slab to forming rollers, reheat the metal in another furnace before forming, and then move the formed steel to another conveyor for further processing, or it Transfer to storage areas, so this is particularly demanding for slab handling cranes, which need to be fast and stable and safe to move over long distances.

Slab clamp crane

Applications: Slab crane uses mechanical or electric clamps to work together, and is designed with a rotating device to ensure the utilization of plant space. ect.

OEM and ODM accepted;

Lower price at same quality;

Drawing provided when need;

24 hours price provided;

Customization production, high efficiency;

Specification

| Lifting Capacity | Span | Lifting Height | Work Duty | Lifting Speed | Crane Traveling Speed | Trolley Traveling Speed | Track | ||

| t | m | m | m/min | m/min | m/min | QU120 | |||

| 35 | 27.5 | 12 | A7 | 1.2~12 | 4.2~42 | 8.5~85 | |||

| 50 | 37 | 12 | 0.95~9.5 | 3.8~38 | 8~80 | ||||

| 65 | 35.5 | 12 | 0.78~7.8 | 3.8~38 | 7.5~75 | ||||

Clamps parallel to the beam:

| Lifting Capacity | Span | Lifting Height | Work Duty | Lifting Speed | Crane Traveling Speed | Trolley Traveling Speed | Track | ||

| t | m | m | m/min | m/min | m/min | QU120 | |||

| 35 | 27.5 | 12 | A7 | 0.95~9.5 | 3.8~38 | 8.5~85 | |||

| 50 | 37 | 12 | 0.95~9.5 | 3.8~38 | 8~80 | ||||

| 65 | 35.5 | 12 | 0.78~7.8 | 3.8~38 | 7.5~75 | ||||

Feature

The slab crane uses mechanical or electric clamps to work together, and is designed with a rotating device to ensure the utilization of plant space.

The intelligent monitoring system cooperates with the workshop production scheduling management system to assist customers in obtaining crane operation information, preventing various sudden failures and reducing downtime.

The hoisting stator is adjusted, frequency conversion operation, stable hoisting operation and small impact.

The main electrical appliance is equipped with an industrial chiller placed in the main beam to ensure a good working environment and temperature.

The overall annealing process of the structural parts ensures the crane performance and installation accuracy.

Generally equipped with a self-propelled mobile cabin or a cabin that travels with the trolley, which is convenient for the crane driver to operate accurately.

Case:

FAQ:

01How do I choose the right Slab Clamp crane?

You can choose according to your needs, or you can consult our experts, we can provide you with the best solution for slab clamp Crane.

02What are the application scenarios of level luffing crane?

Slab Handling Crane is a highly maneuverable electric bridge crane, which is mainly used in steel mills. It usually transports large pieces of hot soft metal, either slabs or billets, from the smelter to its next destination. Melting plants are usually separated from other production sites at some distance because the process is very dangerous.