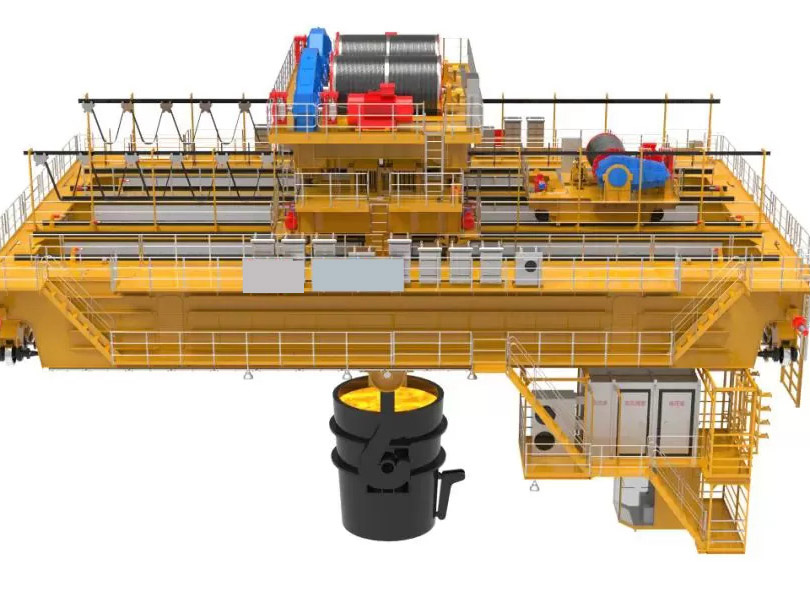

Tundish crane

Capacity (t): 100/32(Double Girder)-320/80(Four Girder)

Span (m) :19.5-24.5

Work Duty: A7

Main Lifting Speed (m/min): 7.5-9

Introduction

As a ladle handling crane used in steel mills, its requirements are very high. It not only has to operate in harsh environments such as high temperature and dust, but also in special circumstances, if the continuous casting machine fails, the tundish crane must It can satisfy the ability to lift a large amount of molten steel, or even the whole package of molten steel.

Its design must meet the requirements of international standards, because the tundish crane is efficient, uninterrupted and safe in continuous use.

For a tundish crane, its lifting capacity depends on the capacity of the tundish. In order to ensure continuous and stable operation, the capacity of the tundish is generally 20% to 40% of the capacity of the ladle. Conventionally, the lifting capacity of tundish cranes is less than 160 tons. Due to different needs, generally such cranes are often tailor-made.

Tundish crane

Applications: Ladle handling crane used in steel mills etc.

OEM and ODM accepted;

Lower price at same quality;

Drawing provided when need;

24 hours price provided;

Customization production, high efficiency;

Specification

| Technical Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity (t) | Span (m) | Lifting Height(m) | Work Duty | Main Lifting Speed (m/min) | Aux Lifting Speed (m/min) | Crab Travelling Speed (m/min) | Trolley Travelling Speed (m/min) | Power (kw) | Rail |

| 100/32(Double Girder) | 19.5~28.5 | 20/22 | A7 | 7.5 | 10.5 | 38 | 68 | 393 | QU120 |

| 100/32(Four Girder) | 19~28 | 20/22 | 7.5 | 12 | 32.5/37.4 | 78 | 426.5 | ||

| 125/32(Double Girder) | 19.5~28.5 | 20/22 | 7.5 | 10.5 | 38 | 79.7 | 479 | ||

| 125/32(Four Girder) | 19~28 | 20/22 | 7.5 | 12 | 38/37.4 | 79.7 | 484.5 | ||

| 140/40(Double Girder) | 22~28 | 22 | 6.8 | 9.1 | 38 | 73 | 479 | ||

| 140/40(Four Girder) | 22~28 | 22 | 6.8 | 9.6 | 38 | 77.8 | 510.5 | ||

| 160/40(Four Girder) | 22~28 | 22 | 0.6~6 | 9.5 | 38 | 77.8 | |||

| 180/50(Four Girder) | 28.5 | 27/29 | 7.2 | 9.3 | 38/40 | 86 | |||

| 200/50(Four Girder) | 28 | 26 | 8 | 9.3 | 40 | 86 | |||

| 225/65(Four Girder) | 27 | 28 | 8 | 10 | 40/38 | 87 | |||

| 240/75(Four Girder) | 24 | 30 | 10 | 10.5 | 38/40 | 87 | |||

| 280/75(Four Girder) | 21 | 24/26 | 10 | 10.5 | 36/39 | 76 | |||

| 320/80(Four Girder) | 24.5 | 28/32 | 9 | 10 | 36/39 | 63 | |||

Feature

Double or triple beam structure.

Safe, reliable, efficient and stable.

The spreader can be replaced flexibly.

Cost-effective and simple maintenance.

Anti-shake system, intelligent control system, equipment operation level.

The equipment is manufactured according to FEM/DIN European standard.

The key electrical system is matched with international big brands.

Intelligent monitoring system to monitor the working status of the crane in real time.

The key system adopts fully redundant design to ensure the safety and reliability of the equipment.

Case:

FAQ:

01How do I choose the right Tundish crane?

You can choose according to your needs, or you can consult our experts, we can provide you with the best solution for Tundish Crane.

02What are the application scenarios of Tundish crane?

Billet Crane is a highly maneuverable electric bridge crane, which is mainly used in steel mills. It usually transports large pieces of hot soft metal, either slabs or billets, from the smelter to its next destination. Melting plants are usually separated from other production sites at some distance because the process is very dangerous.